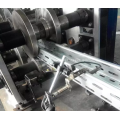

GI stainless Large span Perforated cable tray channel forming machine

Basic Info

Model No.: ZT004

Product Description

Large span cable tray Perforated cable tray channel cable tray stainless steel forming machine

Large span cable tray not only suits the cable laying for oil refining, chemical, textile, mechanical, metallurgic, power, TV and broadcasting industries, but for underground facilities, such as cable channel and structure of subway and defending engineering, etc.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

working flow

Decoiler---punching holes---forming shape---hydraulic cutting---collect final product

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Step 1 : Decoiler

Width for coil:100—600 mm

Thickness of coil: 1~2.0 mm

step 2: Punching system

servo feeder

Step 3 : Forming shape

Roller station quantity: 16

Roller material: 45# steel with chrome

Shaft diameter: 50MM

Shaft material: 45# steel

Roller fixer: separate 45# steel column

Transmission: by gears

Machine base: 20mm 45# steel

Motor power: 7.5k w

Shearing method: hydraulic shearing

Hydraulic station power: 5.5kw

Shearing tolerance: ±1.5 mm.

Control system: PLC

Language : English

step 4: hydraulic shearing

Control Cabinet

Control Cabinet

PLC : Delta

Touch Screen:Siemens

Encoder: Schneider/Mitsubishi

Hydraulic Station

Oil tube: Standrad brand

Solenoid valve:Standrad brand

Cooling systerm: Fans

45#, 46# hydraulic oil

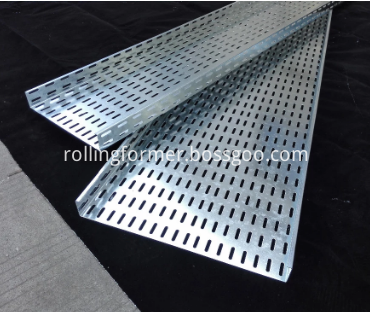

Final product Application

(1) Large span cable tray

Different from normal cable trays, Large span cable tray has large supporting span with high loading capacities. Large span cable tray is assembled by pultruded FRP profiles. Large span cable trays can be divided into ladder style, channel style, perforated style with galvanized, powder coated surface to resist corrosion. They are widely used in heavy corrosive environment to lay computer cables, communication cables, underground cables, thermocouple cables and other sensitive system control cables. As for the installation, large cable trays are combined with many accessories such as corbels, hangers and other fixations.

(2) Stainless steel cable trays

Stainless steel cable trays are suitable for laying cables in chemical and purification plants, refineries, offshore plants, oil and gas tunnels and places where hygiene is of great importance.

(3) ladder cable tray

As the name called, ladder cable tray is a sort of cable tray that is constructed by jointing two longitude channels with horizontal supporting rungs. Ladder cable trays are usually made of stainless steel, aluminum, FRP with hot-dipped galvanized, pre-galvanized, polyester, epoxy, powder coated surface. These trays have large space and perfect ventilation property. Moreover, the ladder style cable trays are less prone to get fire, thus they are the best choice for paper mills, power plants, oil and gas industries and exterior environment.

Installation of cable tray

Product Categories : Cable Tray Forming Machine